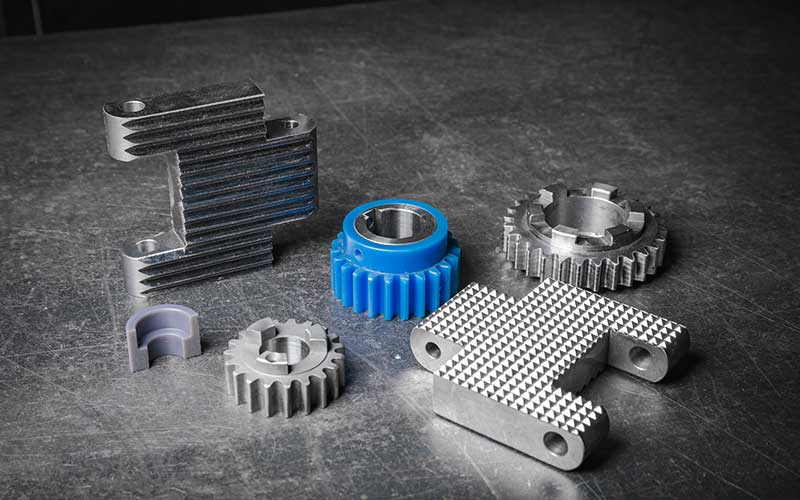

Advanced CNC Machining

Precision Machining Expertise

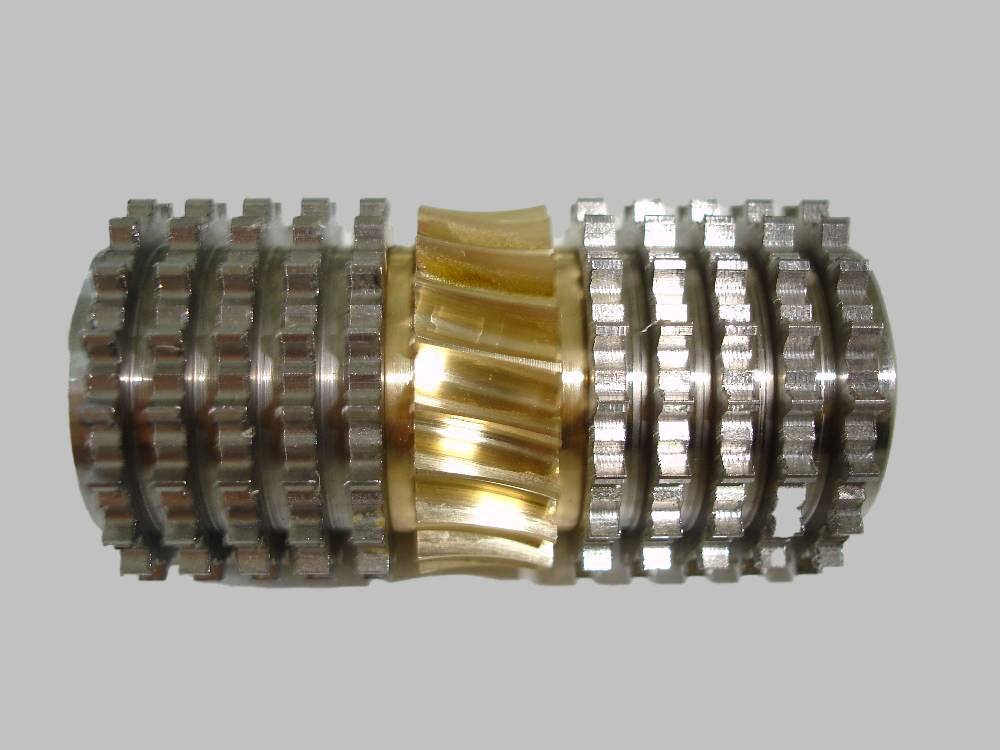

Forged by Experience

Usibeauce leverages its technical know-how and mastery of CNC machining technologies to deliver high-precision parts that meet the most demanding industry standards.

With an experienced team, rigorous processes, and a constant focus on quality, we provide reliable, efficient machining solutions perfectly tailored to our clients’ needs.

The Usibeauce Advantage

Choosing Usibeauce means benefiting from an experienced, cohesive, and passionate team that has developed a true culture of precision and efficiency.

Our consistent quality, combined with the flexibility of a human-sized company, allows us to offer reliable service, on-time delivery, and long-term relationships built on trust.

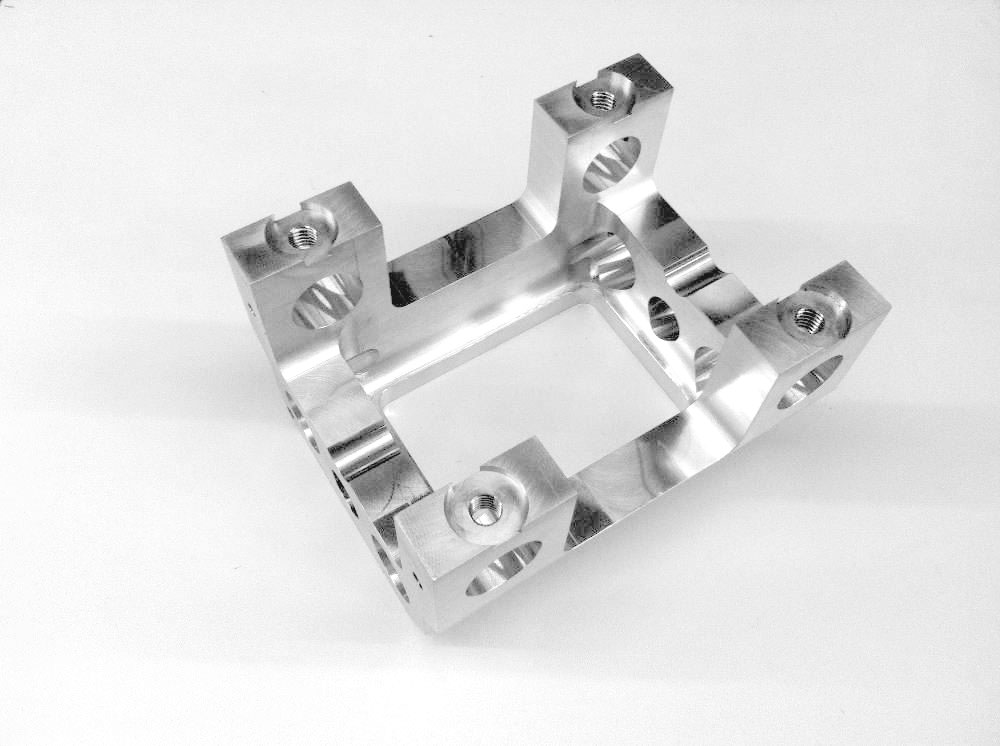

Turnkey Service

Beyond machining, Usibeauce takes care of the entire process to make your life easier.

We can handle material procurement and coordinate with our partners for complementary services such as laser cutting, heat treatment, anodizing, or other metal finishing processes.

This way, you receive your finished parts — ready to use — with the same guarantee of quality and precision.

Ready to proceed?

Our team is available to analyze your needs and offer custom machining solutions tailored to your projects.